Tuesday 21 June 2022

Lithium-ion battery anode Market – Global Forecast to 2026

The global lithium-ion battery anode market size is projected to grow from USD 8.4 billion in 2021 to USD 21.0 billion by 2026, at a CAGR of 19.9% from 2021 to 2026. The growing demand for electric vehicles along with high demand for lithium-ion batteries for industrial applications is driving the market growth. Moreover, strategies such as agreements and plant expansions undertaken by several prominent players in the lithium-ion battery anode industry are further fueling the lithium-ion battery anode industry growth across the globe.

To know about the assumptions considered for the study download the pdf brochure

Based on the end-use, the lithium-ion battery anode market has been segmented into automotive and non-automotive. The non-automotive segment in lithium-ion battery anodes includes energy storage, aerospace, marine, and others. The others segment includes telecommunication, medical, and industrial. The automotive end-use segment is projected to lead the market in terms of both value and volume during the forecast period. The automotive end-use segment was the largest segment in the lithium-ion battery anode market in 2020. Some of the key factors, such as the growth in the demand for electric vehicles in the developing regions of the world and the growing concerns related to environmental issues due to usage of fossil fuels, are resulting in augmenting the automotive end-use segment growth.

The synthetic graphite of lithium-ion battery anode market, by materials, is expected to be the largest market from 2021 to 2026. Synthetic graphite is produced from pitch and coke. It is of a higher purity than natural graphite but is not as crystalline. It is used in specialty applications because of its superior uniformity and purity (>99%). Graphite end users, therefore, prefer synthetic graphite even though its price is three to four times than natural graphite, as synthetics graphite offers higher reliability and performance. Synthetic graphite provides smooth migration of lithium-ions and facilitates fast charge as compared to natural graphite. Therefore, It sees high demand for the lithium-ion battery for anode market during the forecast period.

Asia Pacific, Europe, and North America are significant regional markets for lithium-ion battery anode. The increasing global demand for electric vehicles and rising industrial activities with the high demand for lithium-ion batteries have led to the growth of the lithium-ion battery anode market across the globe. Growing projects related to energy storage and telecommunication in the Asia-Pacific region is also boosting the growth of the market. Various leading manufacturers of lithium-ion battery anode have adopted the strategies of agreements, expansions, acquisitions, collaborations, contracts, investments, and divestments to cater to the increased demand for lithium-ion battery anode from various applications.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=147095907

Monday 20 June 2022

APAC region to lead the global Refrigeration Oil Market by 2026

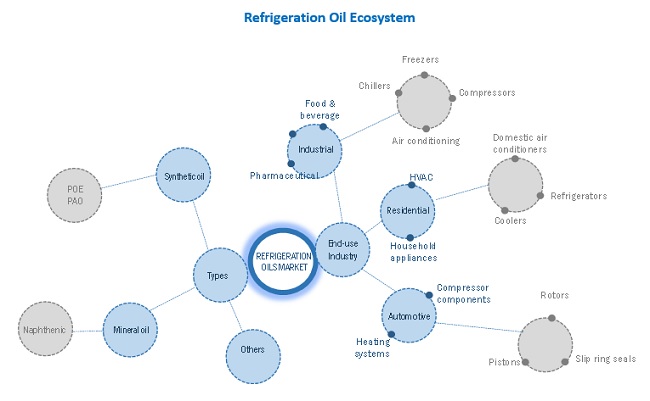

The refrigeration oil market size is projected to reach USD 1.4 billion by 2026 from USD 1.1 billion in 2021, at a CAGR of 4.1%. This growth is primarily triggered by the increasing demand from the refrigerator & freezer, air conditioner, and automotive AC system applications. APAC is the largest refrigeration oil market due to a rise in the manufacturing of consumer appliances and automobiles. Furthermore, the changing lifestyle of consumer and rising income levels have led to higher demand for refrigerators & freezers and air conditioners, which, in turn, drives the refrigeration oil market. The growing demand for perishable food products along with growth in the pharmaceutical industry also drives the demand for refrigerators & freezers, fueling the growth of the refrigeration oil market.

To know about the assumptions considered for the study download the pdf brochure

APAC is an emerging market for the refrigeration oil market, and it is mainly attributed to high economic growth rate, followed by heavy investment across industries such as oil & gas, automotive, infrastructure, chemical, and electronics among others. With economic contraction and saturation in the European and North American markets, the demand is shifting to the APAC region.

Refrigeration oil manufacturers are targeting this region as it is the strongest regional market for various applications, such as automotive, electronics and home appliances among others. The advantage of shifting production to the Asian region is that the cost of production is low here. Also, it is easier to serve the local emerging market.

Key Market Players

The key market players profiled in the report include as Eneos Holdings Inc. (Japan), BASF SE (Germany), Idemitsu Kosan Co. Ltd (Japan), ExxonMobil Corporation (U.S.), Royal Dutch Shell Plc. (Netherlands), Total Energies SE(France), China Petrochemical Corporation (Sinopec Corp), Petroliam Nasional Berhad(Petronas), FUCHS Petrolub SE (Germany), Johnson Controls(Ireland).

Eneos Holdings Inc. is one of the world’s leading manufacturers and innovators of petroleum, natural gas, and metals. . The company operates through four business segments, namely, Energy, Metals, Oil, Natural gas E&P, and Others. . The company operates through four business segments, namely, Energy, Metals, Oil, Natural gas E&P, and Others. The company operates its refrigeration oil business in Japan, China, and other among other countries.

BASF SE is one of the largest chemical producers in the world. It engages in manufacturing and selling a wide range of chemicals and intermediate solutions. The BASF Group comprises subsidiaries and joint ventures in more than 80 countries and operates six integrated production sites and 390 other production sites in Europe, Asia, Australia, America, and Africa. BASF has customers in over 200 countries and supplies products to a wide variety of industries. The company has a presence in more than 60 countries of Europe, North America, APAC, South America, and the Middle East & Africa.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=126068118

Wednesday 15 June 2022

Increasing need for longer life of the equipment is driving the Corrosion Under Insulation (CUI) & Spray-on Insulation (SOI) Coatings Market

Corrosion protection coatings such as CUI & SOI coating are used for the protection of pipelines, equipment, reactors, and storage tanks in oil & gas and industrial sectors. These industries involve the use of hazardous and corrosive chemicals and processes that involve high temperatures and high heat. Also, this equipment is exposed to various climatic conditions which affect the reactor surface. The use of heavy-duty corrosion protection coatings in these areas may prevent or reduce the impact on the reactor surfaces. This results in the extended working life of the equipment.

Due to the competitive market, industries are in the process of cost reduction. Use of heavy-duty corrosion protection coatings for providing insulation results in reduced operating costs.

The global CUI & SOI coatings market size is projected to grow from USD 1.9 billion in 2022 to USD 2.3 billion by 2027, at a CAGR of 4.7%. Worldwide, corrosion under insulation (CUI) causes huge economic losses in many industries. It also gradually weakens structures posing a threat to property and life. CUI & SOI coating is one of the most effective and economical solutions for tackling corrosion. They obstruct the surface and the corrosion agent and extend the life of the structure as well as enhance efficiency.

To know about the assumptions considered for the study download the pdf brochure

The different types of CUI & SOI coatings are epoxy, acrylic, silicone, and others. Epoxy is a major type of CUI & SOI coatings, which accounted for the largest share. This is mainly attributed to excellent protection from CUI, water resistance, and widespread applications of epoxy-based CUI coatings. In addition, epoxy-based CUI & SOI coatings can be used in multi-component coatings with other types.

The market for CUI & SOI coatings in APAC is projected to register significant growth, and this trend is projected to continue during the forecast period. Asia Pacific is the fastest-growing CUI & SOI coatings market globally. This is attributed to economic growth, followed by large investments in various industries such as petrochemical, oil & gas, marine, energy & power, and others. APAC is the most lucrative market and should be the same in the near future.

APAC is the center of foreign investments and booming manufacturing sectors due to the low-cost labor and inexpensive availability of land. The rise in demand for CUI & SOI coatings can be ascribed to the growing marine, oil & gas, and petrochemical industries. These factors are contributing to the rising demand for CUI & SOI coatings in the Asia Pacific.

Major players operating in the CUI & SOI coatings market include Akzo Nobel N.V. (Netherlands), PPG Industries, Inc., (US), Jotun A/S (Norway), The Sherwin-Williams Company (US), Hempel A/S (Denmark), Kansai Paint Co., Ltd (Japan), Nippon Paint Co., Ltd. (Japan), and RPM International Inc (US).

Read More: https://www.marketsandmarkets.com/ResearchInsight/corrosion-under-insulation-cui-spray-on-insulation-soi-coatings-market.asp

Monday 13 June 2022

Chromatography Resin Market Opportunity: Growing demand in drug development and omics research

Chromatography represents the most versatile separation technique and is readily available. At the early stage of drug discovery, many closely related compounds are synthesized and are required to be separated. Their identification and purity testing are very essential. Chromatography techniques are widely used for these applications. Chromatography instruments have applications in the separation, purification, and analysis of raw materials, Active Pharmaceutical Ingredients (APIs), and excipients. Thus, the growing requirements for high-quality drugs and implementation of stringent government initiatives are increasing the demand of chromatography resin in several countries.

To know about the assumptions considered for the study download the pdf brochure

Synthetic resins segment is projected to register the highest CAGR between 2022 and 2027. The demand for synthetic resins is expected to be driven by their use in ion-exchange chromatography. Polystyrene divinylbenzene is the most commonly used synthetic resin, which is increasingly used in IEX technique because of its better performance characteristics in comparison to natural polymers. The growth of the synthetic resins segment is projected to be driven by its increasing use in analytical or laboratory-scale applications.

Affinity was the largest chromatography technique in 2021 in terms of value

The affinity chromatography technique is based on the selective affinity of molecules in the mobile phase toward ligands coupled to the stationary resin. The rising demand for protein A for convenient and efficient antibody purification is expected to drive the affinity chromatography segment. Affinity chromatography offers high selectivity, resolution, and capacity in most protein purification schemes. It has the advantage of utilizing a protein’s biological structure or function for purification. All these factors drive the demand for affinity technique

North America accounted for the largest share of the global chromatography resin market, in terms of both volume and value, in 2021. The US is the leading market for chromatography resin in North America, followed by Canada. A strong therapeutic monoclonal antibody market in North America is one of the key drivers for chromatography resin market. Modern chromatographic techniques are also increasingly used in food analytics and other diagnostic purposes in the US as well as in Canada. Most of the key pharmaceutical companies have their research centers in North America. All these factor drive the demand for chromatography resin in North America.

The chromatography resin market is donimated by a few globally established players such as Danaher Corporation (US), Bio-Rad Laboratories Inc. (US), Merck KGaA (Germany), Tosoh Corporation (Japan), BioWorks Technologies AB (Sweden), Kaneka Corporation (Japan), Avantor Performance Materials, Inc (US), Purolite Corporation (US), Repligen Corporation (US), AND Thermo Fisher Scientific Inc. (US).

Read More: https://www.marketsandmarkets.com/PressReleases/chromatography-resins.asp

Cardolite Company(U.S.A) and Pelmer International(U.S.A) are leading players in Cashew Nutshell Liquid Market

The CNSL market size is estimated to be USD 393 million in 2022 and is projected to reach USD 564 million by 2027, at a CAGR of 7.5% between 2022 and 2027. Increasing demand from the chemical and petrochemical industries, the rising demand for natural resources for various applications are significantly driving the market globally.

The CNSL market in Europe is segmented into Germany, France, the UK, Italy, the Netherlands, and Rest of Europe. The chemical industry is a significant part of the region’s economy. The growth is driven by investments made in this region by global chemical companies. Though the steady European economic recovery is expected to drive the market, the adoption of several strict regulations against the use of petroleum-based products is likely to challenge the market growth in the region.

To know about the assumptions considered for the study download the pdf brochure

The key market players are cardolite company(U.S.A), pelmer international(U.S.A), senesel(Poland), sri devi group(India).

Cardolite Corporation is a manufacturer of CNSL-based products used in coatings, friction materials, adhesives, composites, and foams. The company is the leader in the production of quality CNSL-based materials. Cardolite delivers high-quality products and services across the globe and has sales offices, representatives, and distribution facilities in the Americas, Europe, and Asia.

Palmer International is a global leader in CNSL technology. The company provides polyols, chemicals, friction particles, and resins to automotive, transport, construction, and other industries worldwide. It is the world’s oldest producer of cashew derivatives and a leader in developing OEM friction particles. The company is the worlds leading producer of cashew-manic polyols and epoxy hardener chemistry.

Read More: https://www.marketsandmarkets.com/PressReleases/cashew-nutshell-liquid.asp

Tuesday 7 June 2022

Packaging Industry Dominated Bioplastics & Biopolymers Market in Apac

Global bioplastics & biopolymers market size is projected to grow from USD 10.7 billion in 2021 to USD 29.7 billion by 2026, at a CAGR of 22.7% between 2021 and 2026. Bioplastics are plastics derived from renewable sources such as corn, potatoes, rice, soy, sugarcane, wheat, and vegetable oil, while biopolymers are naturally occurring polymers. A bioplastic may or may not be biodegradable. Bioplastics are mainly segmented into biodegradable and non-biodegradable plastics for various applications in the packaging, consumer goods, automotive & transportation, agriculture & horticulture, medical, and other end-use industries.

To know about the assumptions considered for the study download the pdf brochure

Packaging is the largest end-use industry for the application of bioplastics & biopolymers. They accounted for the share of 61.6%, in 2020, for the global bioplastics & biopolymers market. Increasing environmental regulations and changes in the lifestyle of consumers have increased the demand for bioplastics & biopolymers in the packaging industry. Plastics have high durability and impermeability to water, which has encouraged their use in packaging. Packaging applications of bioplastics & biopolymers include food packaging, healthcare packaging, cosmetic & personal care packaging, shopping bags, and others.

High potential in emerging countries of APAC

The bioplastics & biopolymers market players are continuously implementing organic and inorganic strategies for their growth. In recent years, the players have made many strategic developments in the emerging countries of APAC. For instance, in 2019, Total Corbion set up a PLA Plant in Rayong, Thailand, with a production capacity of 75,000 tons per year. In the same year, Mitsubishi Chemical Holding Corporation (Japan) and Lenovo Group Limited (China) entered into a joint venture to produce a bioplastic-based body (3D shape rear panel) for smartphones. In addition, Indonesia is exploring bioplastic alternatives, such as seaweed. Evoware, a local player, provides patented seaweed-based packaging. The company is producing containers made from seaweed. The regulations related to the environment are expected to increase, which would eventually propel the demand for bioplastics in these countries in the future. Moreover, Southeast Asia is rich in bio-based feedstock required to produce bioplastic as it has local access to sustainable raw materials. Thus, regulations, coupled with the easy availability of feedstock, will, in turn, help sustain the demand for bioplastics during the forecast period.

The key players in this market are NatureWorks (US), Braskem (Brazil), BASF (Germany), Total Corbion (Netherlands), Novamont (Italy), Biome Bioplastics (UK), Mitsubishi Chemical Holding Corporation (Japan), Biotec (Germany), Toray Industries (Japan), and Plantic Technologies (Australia).

Read More: https://www.marketsandmarkets.com/ResearchInsight/biopolymers-bioplastics-market.asp

Monday 6 June 2022

Growth of the geosynthetics market can be attributed to increasing investments in waste management in emerging economies

The global geosynthetics market is projected to reach USD 13.2 billion by 2026 from USD 9.9 billion in 2021, at a CAGR of 6.0% between 2021 and 2026.

Rapidly increasing population and urbanization is contributing in increasing levels of solid and liquid wastes across the globe. Rising environmental awareness is leading to an increase in the demand for appropriate waste and water management projects. Geosynthetics are used as landfill caps to prevent the migration of fluids into landfills by reducing or eliminating the post-closure generation of leachate and associated treatment costs. Geosynthetics are widely used in various water management activities owing to the increasing public concerns in serious and widespread water pollution. Geosynthetics liner systems are used in waste treatment lagoons at wastewater treatment plants to protect water resources including lakes, rivers, ponds, aquifers, and reservoirs which is expected to boost the demand for geosynthetics during the forecast period.

To know about the assumptions considered for the study download the pdf brochure

Waste management contributes for the largest market share for the geosynthetics market in 2020. Geosynthetics are used in waste management for performing various functions such as filtration, separation, drainage, barrier, and reinforcement. It includes the proper collection, transport, treatment, recycling, and disposal of residential, industrial, and commercial waste. Geosynthetics are essential for controlling the leakage of contaminated gas and liquid into groundwater, rivers, aquifers, and other freshwater sources. The rising demand for waste management owing to increase in population, urbanization, and industrialization is expected to drive the geosynthetics market during the forecast period.

Geosynthetics market is dominated by APAC in 2020. The region is growing at a faster rate which accounts for the high growth of the geosynthetics market. The emerging market of India, China, and other countries of the APAC are growing and boosting the regional market growth. Rapidly increasing population, urbanization, and industrialization are expected to drive the geosynthetics market in APAC. Rising investment In the development of public infrastructure and growing demand for solid waste management system are the major factors driving the geosynthetics demand in the region.

Key players in the geosynthetics market are SOLMAX (Canada), NAUE GmbH & Co. KG (Germany), Officine Maccaferri Spa ( Italy), Berry Global Inc ( US), and Agru America, Inc ( US) are the major players in the market.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=1174

Non-Biodegradable Plastics to Lead Bioplastics & Biopolymers Market During Forecast Period

In recent years, there has been a growing awareness that the use of non-biodegradable plastics is leading to large amounts of plastic waste ...

-

The global polylactic acid market is projected to reach $43.7 billion by 2024, growing at a CAGR of 5.2% from 2018. The industry is charact...

-

New product launches and expansions are the key strategies adopted by the industry players to achieve growth in the polyurethane additive...

-

If you have found yourself in search of a water treatment application that would help you capture the largest share of the corrosion inhibit...