Monday, 22 March 2021

The European region is expected to be the largest market for aroma ingredients

The aroma ingredients market is projected to grow from USD 2.27 billion in 2018 to USD 2.83 billion by 2023, at a CAGR of 4.5% between 2018 and 2023. The increasing demand for personal care products, coupled with the change in lifestyles and consumer preferences is expected to drive the growth of the aroma ingredients market.

The aroma ingredients market has been studied for 5 regions, namely, APAC, North America, Europe, the Middle East & Africa, and South America. The European region is projected to be the largest market for aroma ingredients during the forecast period due to the strong foothold of manufacturers of personal care products in the region. Aroma ingredients are the key compounds used in the formulation of various personal care products. The European region is also home for the leading manufacturers of aroma ingredients. The major countries driving the growth of the aroma ingredients market in the European region are France, Germany, Italy, and UK.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=113835443

Some of the key players in the aroma ingredients market include Symrise (Germany), Takasago International Corporation (Japan), Sensient Technologies Corporation (US), MANE (France), Robertet SA (France), T. Hasegawa Co., Ltd. (Japan), Frutarom (Israel), Givaudan (Switzerland), Firmenich SA (Switzerland), and International Flavors & Fragrances Inc. (US).

Browse 64 market data Tables and 41 Figures spread through 110 Pages and in-depth TOC on “Aroma Ingredients Market for Personal Care Industry by Type (Synthetic Ingredients, Natural Ingredients), Application (Fine Fragrances, Toiletries, and Cosmetics), and Region (APAC, Europe, North America) – Global Forecast to 2023”

https://www.marketsandmarkets.com/Market-Reports/aroma-ingredient-market-113835443.html

Friday, 19 March 2021

APAC to dominate the microporous insulation market

Microporous insulation is a composite material comprising of a blend of ceramic powders and fibers, with an average interconnecting pore size comparable to or even less than the mean free path of air molecules at standard atmospheric pressure. It may contain opacifiers to reduce the amount of the radiant heat transmitted. The microporous insulation material is inorganic making it non-combustible and suitable for passive fire protection applications. It is ideal for any high-temperature application and has been used in aerospace, automotive, industrial, and commercial markets where space and weight conservation are critical requirements without compromising the thermal performance.

The rising awareness about the benefits of microporous insulation materials and growing industrialization and infrastructure development in the APAC region offer various opportunities regarding the use of microporous insulation. Also, the increase in demand for energy, power, metal, and automotive, is expected to drive the market. The microporous insulation market is significantly driven by the oil & gas segment, where there is a high demand for advanced insulation solutions, having a reduced thickness and low thermal conductivity.

The global microporous insulation market size was USD 125.8 million in 2017 and is projected to reach USD 165.4 million by 2023, at a CAGR of 4.7%. Additionally, the microporous insulation market is expected to grow from 3,800 metric tons in 2018 to 4,608 metric tons by 2023, at a CAGR of 3.9% during the forecast period. Its unique property of space and weight conservation in the aerospace & defense application will drive the growth of this market.

The demand for microporous insulation is increasing in the aerospace application due to increasing demand for light-weight materials, which in turn, saves the fuel consumed during operation of an aircraft. In addition, the use of microporous insulation provides high performance and helps to meet the space and weight specifications in the aerospace sector. It is the most demanding sector in terms of performance & reliability due to operational and safety reasons.

The key players in the microporous insulation market include Promat International N.V. (Belgium), Morgan Advanced Materials plc (UK), Isoleika S. Coop. (Spain), Unicorn Insulations Ltd. (China), Guangzhou Huineng Environmental Protection Materials Co., Ltd. (SILTHERM) (China), Johns Manville (US), Nichias Corporation (Japan), ThermoDyne (US), Unifrax (US), and Elmelin Ltd. (UK).

Browse 106 market data Tables and 37 Figures spread through 138 Pages and in-depth TOC on “Microporous Insulation Market by Product Type (Rigid boards & panels, flexible panels, machined parts, moldable products), Application (Industrial, Energy & Power, Oil & Gas, Aerospace & Defense, Automotive), and Region – Global Forecast to 2023”

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=129425481

Wednesday, 17 March 2021

North America to account for the largest share of the healthcare adhesive tapes market

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=175119477

Various factors have contributed to the growth of the North American healthcare adhesive tapes market. These factors include the rising incidence of chronic wounds, increase in the number of elderly citizens, increasing patient awareness on wound care, aging population, and technological advancements in the healthcare industry. The surgical adhesive tapes application has witnessed steady growth along with an increase in orthopedic and trauma, neurosurgery, cardiovascular, and gastroenterology. The increasing number of orthopedic procedures in the US is driving the demand for bandages and healthcare adhesive tapes.

Recent Developments

- In July 2017, Cardinal Health (US) acquired Medtronic’s Patient Care, Deep Vein Thrombosis and Nutritional Insufficiency business for USD 6.1 billion. This acquisition provides product offerings which are used across a wide range of applications in the healthcare industry.

- In May 2017, Avery Dennison acquired Finesse Medical, an innovator of healthcare products used in the management of wound and skin conditions. With a revenue of approximately USD 17.11 million over the last year, the company is a key supplier to global healthcare-product OEMs and also provides contract manufacturing and product development services. This acquisition will accelerate the achievement of Avery Dennison’s long-term strategic and financial goals for industrial and healthcare materials segment

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=175119477

Monday, 15 March 2021

Consumer & DIY is the fastest-growing application of the hot melt adhesive tapes market

Increasing public awareness for DIY is fueling the use of these tapes in different activities, such as gardening, crafting, and small construction & furniture projects. A majority of these tapes are used for different office and household applications. The consumer & DIY applications of hot melt adhesive tapes include temporary repairing of rips on any kind of surface, sealing of leaks and holes, temporary mounting of damaged components of cars and automobiles, jointing of broken components of various tools, sealing, and packaging. Hence, the demand for consumer & DIY applications is high in the hot melt adhesive tapes market.

The market size of hot melt adhesive tapes is projected to grow from USD 15.5 billion in 2019 to USD 21.7 billion by 2024, at a CAGR of 7.0%, during the forecast period. The global hot melt adhesive tapes market is witnessing high growth on account of increasing applications, technological advancements, and growing demand in the APAC region. Growing packaging market in emerging economies is a key factor providing growth opportunities to the market.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=138739970

The demand for hot melt adhesive tapes has increased in APAC countries, such as South Korea, Singapore, India, and Indonesia, as the application activities in these countries have risen. China has been the driving force for the rapid expansion of the adhesive tapes market, not only in APAC, but also worldwide. In several countries, the factors affecting the packaging, which is a major application of hot melt adhesive tapes, are the increasing level of disposable income and population growth. These factors are positively influencing the hot melt adhesive tapes market growth.

Recent Developments

In December 2016, LINTEC Corporation acquired MACtac Americas Holdings, LLC, manufacturer and distributor of adhesive papers and films for printing in the US to get a full-scale entry into the North American market.

In July 2016, the company made a USD 20 million expansion by adding 24,000 square feet to its current Sparta facility. This facility is expected to add to the production of strapping tapes and acrylic adhesives, which will be used for healthcare applications of the hot melt-based adhesive tapes.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=138739970

New Product Developments, Acquisitions, and Collaboration to Enhance their Position in the Asphalt Additive Market

The asphalt additive market is projected to grow from USD 3.6 billion in 2019 to USD 4.6 billion by 2024, at a CAGR of 5.1% from 2019 to 2024. Increase in infrastructure development and road construction projects is one of the key factors driving the growth of the asphalt additive market across the globe.

Nouryon (Netherlands), DowDuPont (US), Arkema SA (France), Honeywell International Inc. (US), Evonik Industries (Germany), Huntsman Corporation (US), Kraton Corporation (US), Sasol Limited (South Africa), Ingevity Corporation (US), Arrmaz (US), BASF SE (Germany), and Kao Corporation (Japan) are some of the leading players operating in the asphalt additive market. These players have adopted the strategies of expansions, new product developments, acquisitions, and collaboration to enhance their position in the market.To know about the assumptions considered for the study download the pdf brochure

The Asia-Pacific region was the largest market for asphalt additives in 2018, owing to the increasing demand for asphalt additives products in developing economies, such as India and China. China is the leading consumer of asphalt additives products in the Asia-Pacific region. The considerable growth and innovation, along with industry consolidations, is expected to drive the growth of the Asia-Pacific asphalt additives market.

In February 2018, Sasol Limited (South Africa) celebrated the completion of the expansion of USD 1.13 billion Fischer-Tropsch Wax Expansion Project (FTWEP) in South Africa. The plant is operated under Sasol Performance Chemicals which manufactures hard waxes, medium waxes, liquid paraffin, and waxy oils for various industrial applications, including hot-melt adhesives, polyvinyl chloride processing, and asphalt applications. The plant is expected to have a production capacity of 137,000 tons per year. This expansion aims at strengthening the position of the company in the South Africa asphalt additive market.

In February 2019, a subsidiary of Arrmaz (US), RoadScience launched a new asphalt emulsifier, ArrTekk. This product is used to provide the required viscidity across asphalts for efficient and cost-effective chip sealing. These products provide better rutting resistance, high cold-temperature performance, and are water resistant. This development helped the company to enhance the depth of its product line.

Speak to Analyst: https://www.marketsandmarkets.com/requestsampleNew.asp?id=156734514

Friday, 12 March 2021

5 Latest Development in Polyetherimide (PEI) Market

The Polyetherimide (PEI) Market is projected to grow from USD 522 million in 2019 to USD 714 million by 2024, at a CAGR of 6.5% during the forecast period. PEI is a high-performance polymer with both ether links and imide groups in its polymer chain. It is used in high-temperature applications where fast dissipation of heat is essential. Due to its creep resistance, low smoke emission, and flame resistance, the demand for PEI as a thermally conductive plastic has increased significantly. PEI, along with thermally conductive fillers, is a cost-effective solution to metals due to lesser manufacturing steps and joints. PEI is widely used as an alternative to metals in compact electronic gadgets, as it increases the performance of compact electronics by heat dissipation. In addition to the electronics industry, PEI is used in transportation, medical, consumer good, and industrial end-use industries.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=264439177

The key countries contributing to the growth of the PEI market in Europe are Germany, France, the UK, Italy, and Spain. Favorable government policies are expected to provide growth opportunities for R&D in the electronics & semiconductor and automotive industries in these countries. The growth in R&D investment in the region is mainly driven by the automotive, information and communications technology (ICT), and healthcare industries, which is expected to boost the demand for PEI in the region.

Recent Developments

- SABIC (Saudi Arabia) launched polyetherimide (PEI) film – ULTEM film UTF120. This new product is designed to address the increasing need for high energy density capacitors that can store a large amount of electrical energy for a long period without the loss of charge. This product has application in the electrical & electronics end-use industry. Potential applications of the product include automotive components, electrical compressors, LED lighting, and LCD backlight in electronics and film capacitors in renewable energy.

- SABIC announced plans to expand capacity for ULTEM resin production in Singapore, aiming to increase global production by 50%. This has helped the company to localize its production for customers in Asia and meet increasing customer demands.

- RTP Company started a new 86,000 square foot manufacturing facility in Wroclaw, Poland, and this will help the company to support the regional demand and will offer a consistent supply in Europe.

- The Röchling Group inaugurated its second plant in Vadodara with an investment of around 200 million rupees. This expansion will help the company to grow its roots in the Indian subcontinent and meet the demand of the region.

Speak with analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=264439177

Thursday, 11 March 2021

Increasing demand for cosmetic pigments in personal care products driving the Market

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=179525453

APAC is the fastest-growing market, in terms of both production and demand. Higher domestic demand, easy availability of raw materials, and low-cost labor make APAC the most preferred destination for the manufacturers of cosmetic pigments. The use of cosmetic pigments as an important additive in various applications such nail products, lip products, eye makeup, facial makeup, hair color products, special effect & special purpose as is driving the market in China. APAC is emerging as a leading consumer of cosmetic pigments due to the increasing demand from domestic as well as international markets.

The market size of cosmetic pigments is estimated at USD 698 million in 2019 and projected to reach USD 1,019 million by 2024, growing at a CAGR of 7.9%. The global cosmetic pigments market is driven by the growing demand from color cosmetic and personal care applications. Increased need for product differentiation and growing awareness about the improved appearance of products are boosting the market.

Recent Developments

- In June 2019, BASF and siHealth Ltd (UK) announced a strategic alliance, to exclusively market scientifically-based satellite and optronic technologies to the personal care industry globally. This partnership is expected to extend BASF’s offerings, enabling new solutions to the personal care industry.

- In February 2019, Sun Chemical introduced its new SpectraFlex illusion pigments for soft-focus effects. SpectraFlex Illusion soft-focus effect pigments are used in daily wear makeup primers to help optically blur fine lines and other imperfections. This launch helped the company in strengthening its product offering for personal care applications, such as face powders, body powders, foundation, and other skincare applications.

Request for sample report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=179525453

Wednesday, 10 March 2021

North America is expected to lead the thermoforming plastic market

The thermoforming plastic market size is growing due to the rising healthcare & pharmaceuticals and food & agriculture packaging industries and increasing manufacturing activities. The increasing popularity of retail shopping and rising consumer spending for processed & packed goods are fueling the demand for thermoforming plastic. Factors such as changing demographics and lifestyles have shifted the market toward e-retailing channels and convenient packaging, which in turn will drive the demand for thermoforming plastic. The thermoforming plastic industry is expected to grow from USD 34.8 billion in 2019 to USD 45.9 billion by 2024, at a CAGR of 5.7% during the forecast period.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=97181143

North America accounted for the largest share in the global thermoforming plastic market in 2018. Technological advancements in the packaging industry primarily drive the market in this region. The demand for thermoforming plastic will be driven by factors such as increasing electronic goods sales, high disposable income, increasing demand for packaged foods, and demographic changes. The region is characterized by continuous technological advancements in the thermoforming plastic industry with the presence of some key regional players such as Pactiv LLC, Sonoco Products Company, D&W Fine Pack LLC, Fabri-Kal Corporation and Dart Container Corporation.

The US is a key market in North America. The increasing demand for consumer durables will drive the market for in the U.S. as thermoforming plastic finds growing use in it. The demand for thermoforming plastic in the US is likely to witness robust growth during the forecast period, as a result of the rising trend of retail shopping.

Sabert Corporation (US) is one of the prime manufacturers of thermoforming plastic in the North American region. Sabeart Corporation is a leading manufacturer of innovative food packaging products and solutions for food distributors, restaurants & caterers, grocery stores, national food chains, and consumer entertaining. The company provides a variety of food packaging for displaying, serving, & storing fine food. The company also recycles plastics going to landfill in Riverside, CA facility. The main products provided by the company include Catering Collection Packaging, Green Collection Packaging, Hot Collection Packaging, Cold Collection Packaging, and Bakery Collection Packaging. It is involved in implementing business strategies such as expansion, and acquisition to increase its market share around the globe. For instance, in February 2018, Sabert Corporation expanded its manufacturing facility, located in Greenville, Texas, for manufacturing 100% compostable packaging made from plant-based materials. This helped the company to deliver more options to its customers.

The thermoforming plastic market comprises major solution providers, such as Fabri-Kal Corp. (US), Berry Global Inc. (US), Genpak LLC (US), Pactiv LLC (US), D&W Fine Pack LLC (US), Amcor Ltd. (Australia), Dart Container Corp. (US), Anchor Packaging (US), Sabert Corporation (US), Sonoco Products Company (US). The study includes an in-depth competitive analysis of these key players in the thermoforming plastic market, with their company profiles, recent developments, and key market strategies.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=97181143

Tuesday, 9 March 2021

Emerging demand for furfural derivatives in various applications driving the furfural market

An increase in the demand for spandex from the textile & apparel industry is being witnessed due to its high strength and elastic properties. The changing textile industry and increasing awareness about health have helped the growth of the spandex fibers market in recent years. This is likely to drive the market for PTMEG, which is an application of THF. THF is one of the furan derivatives manufactured with the use of furfural. Polyurethane (PU) is another chemical, which is produced from PTMEG. PU is widely used in various industries, such as apparel, appliances, automotive, construction, flooring, furnishing, marine, and medical. PU foam is highly preferred for automotive interiors and also for thermal insulation in buildings due to its energy efficiency properties. China is the major consumer and producer of PU in the world, and hence a favorable market scenario in APAC is expected to drive the demand for PU during the forecast period, in turn creating opportunities for the furfural manufacturers..

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=101056456

The global furfural market size is projected to grow from USD 551 million in 2019 to USD 700 million by 2024, at a compound annual growth rate (CAGR) of 4.9% between 2019 and 2024. Increasing demand from various end-use industries such as foundry, pharmaceutical, and textile is the primary factor driving the furfural market.

APAC led the overall furfural market in 2018. The main reason for the growth of the market in the region is China, which has 85% and 75% of global production and consumption of furfural, respectively. The demand is attributed to the growing foundry and pharmaceutical industries in China. The presence of large manufacturing capacities in the country has resulted in lower prices of furfural, thereby affecting the other players in the market. As a result, anti-dumping duties were levied on Chinese imports by the US. EU also had anti-dumping duties against Chinese imports, but it was later removed in 2012. Thailand is also one of the key exporters of furfural in APAC.

The leading players in the furfural market are Transfuran Chemicals (Belgium), Central Romana Corporation (Dominican Republic), Pennakem (US), Silvateam (Italy), Illovo Sugar (South Africa), Hongye Holding Group Corporation (China), KRBL(India), Lenzing (Austria), Tanin (Slovenia), and Shandong Crownchem Industries (China).

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=101056456

Monday, 8 March 2021

Demand for polybutadiene in the automotive industry for manufacturing tires is expected to be driven by the growing automotive sales

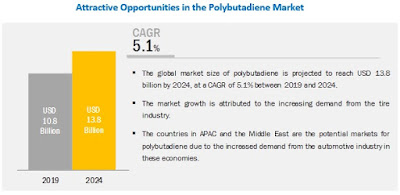

The polybutadiene market size is expected to grow from USD 10.8 billion in 2019 to USD 13.8 billion by 2024, at a CAGR of 5.1% during the forecast period. The polybutadiene market is driven by tire, polymer modification, and industrial rubber manufacturing industries. However, the fluctuating raw material prices can hinder the growth of the market.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=56692050

Emerging economies such as China, India, Indonesia, and Thailand are experiencing high demand for polybutadiene. Increasing disposable income, huge consumer base, rising urban population, low labour costs, and easy availability of raw materials are attracting global automobile manufacturers to shift their production facilities to the region, thus, creating a high demand for polybutadiene in this region.

Tire application accounts for largest market size during forecast period

The tire industry is expanding due to the growing automotive industry. It accounted for the largest share of the overall polybutadiene market. Furthermore, this segment is estimated to grow significantly during the forecast period. Polybutadiene is widely used in tire manufacturing due to its toughness, good abrasion resistance, cold resistance, high tensile strength, high resilience, tear resistance, and durability.

APAC is estimated to account for the largest value share of the global polybutadiene market. The market is primarily driven by the strong demand from the automotive industry. China is expected to boost the demand for polybutadiene during the forecast period. Increasing disposable income, huge consumer base, rising urban population, low labor costs, and easy availability of raw materials are attracting global automobile manufacturers to shift their production facilities to the region, thus, creating a high demand for polybutadiene in this region.

Recent Developments

In February 2019,SIBUR decided to launch an investment project aimed at enhancing polybutadiene rubber (Nd-BR) production efficiency at its Voronezh facility (Voronezhsintezkauchuk). The project aims for a large-scale upgrade to boost operational efficiency of the existing facility and ensure production of consistently high quality of products. This project will enable SIBUR to produce quality products with improved operational efficiency.

ARALNXEO (Netherlands), UBE Industries Ltd (Japan), JSR Corporation (Japan), Kumho Petrochemical Co. Ltd (South Korea), Reliance Industries Ltd. (India), SABIC (Saudi Arabia), LG Chem Ltd (South Korea), Versalis SPA (Italy), PJSC SIBUR Holdings (Russia), Sinopec (China), and Kuraray Co. Ltd (Japan) are some of the major manufacturers of the polybutadiene market. The study includes in-depth competitive analysis of these key players in the polybutadiene market, with their company profiles, recent developments, and key market strategies.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=56692050

Tuesday, 2 March 2021

Graphene Battery Market worth $609 million by 2030, at a CAGR of 23.9%

The global graphene battery market size is projected to grow from USD 168 million in 2024 to USD 609 million by 2030, at a CAGR of 23.9% from 2024 to 2030. The market growth is driven by the advantages of graphene that is used as a battery material in graphene batteries and increasing demand for these batteries in consumer electronics and automotive industries.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=96975481

The lithium-ion graphene battery segment is estimated to account for the largest share of the market in 2021

Graphene lithium-ion batteries are consumed by end-use industries such as consumer electronics, automotive, industrial, power and others due as they are light, durable and suitable for high capacity energy storage, as well as shortens the charging times. The lithium-ion graphene battery segment is forecasted to have the highest growth rate owing to the increasing demand for lithium-ion batteries compared to other batteries due to its various applications in the consumer electronics and automotive industries.

The automotive end-use industry segment is estimated to account for the largest share of the market in 2021

The need for high power and energy density has created a demand for reliable and safe batteries for industries such as automotive and consumer electronics, ultimately driving the growth of the graphene battery market. Graphene batteries are used in electric vehicles in the automotive industry. The automotive segment is forecasted to have the highest growth rate owing to the rise in the demand for electric vehicles due to environmental concerns and awareness about clean and sustainable fuel.

The Asia Pacific region is expected to account for the largest share of the market in 2021. In China, Japan and South Korea along with electric vehicles, graphene batteries are used in consumer electronics. Europe is estimated to have the second-largest share of the global graphene battery market in 2021.

Samsung SDI (South Korea), Huawei Technologies Co., Ltd. (China), Log 9 Materials Scientific Private Limited (India), Cabot Corporation (US), Grabat Graphenano Energy (Spain), Nanotech Energy (US), Nanotek Instruments, Inc. (US), XG Sciences, Inc. (US), ZEN Graphene Solutions Ltd. (Canada), Graphene NanoChem (Malaysia), Global Graphene Group (US), Vorbeck Materials Corp. (US), Graphenea Group (Spain), Hybrid Kinetic Group Ltd. (Hong Kong) and Targray Group (Canada) are some of the leading players operating in the graphene battery market.

Inquiry Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=96975481

Monday, 1 March 2021

5 Latest Developments In Epoxy Adhesives Market

The global epoxy adhesives market size is projected to grow from USD 7.2 billion in 2019 to USD 9.6 billion by 2024, at a CAGR of 6.0% between 2019 and 2024. Increasing urbanization growing usage of composites, plastics, and other higher strength metals in the construction industry are driving the global epoxy adhesives market. Epoxy adhesives are used in various applications due totheir exceptional bonding and mechanical & electrical insulating properties and resistance to chemicals andheat.

The key epoxy adhesive market players are Henkel AG (Germany), Sika AG (Switzerland), 3M Company (US), H.B. Fuller (US), DuPont (US), Illinois Tool Works Incorporation (US), Ashland (US), RPM International (US), Lord Corporation (US), Huntsman Corporation (US), Mapie S.p.A. (Italy), Panacol-Elosol GmBH (Germany), Permabond LLC. (UK), Delo Industrie Klebstoffe GmBH & Co. KGAA (Germany), and Masterbond Inc. (US). These players have adopted growth strategies, such as new product development, merger & acquisition, and investment & expansion, to expand their geographical presence and broaden their product portfolio.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=142980020

Recent Developments

- Henkel invested USD 39.4 billion in June 2019 and opened a new European hub for high-performing aerospace solutions in Spain. This expansion has helped to provide high-performance epoxy adhesive solutions for the constantly growing demand and concentrate on the key trends in the global aerospace industry such as light-weighting, fuel efficiency, and automation.

- In April 2019, Henkel opened a new OEM application center in Connecticut to deliver innovative solutions and design customized applications, technologies, and production processes to better serve its customers.

- H.B. Fuller established an engineering adhesives business in Japan in March 2019. This expansion has strengthened its engineering adhesive (EA) businesses in Japan by focusing on high-performance epoxy adhesives, including reactive adhesive chemistries and applications.

- Henkel completed the acquisition of all shares of Aislantes Nacionales S.A., Santiago, Chile in December 2018. Following this acquisition, Henkel is now active in the attractive Chilean market for tile adhesives and building materials where it occupies a strong position.

- In July 2018, Henkel added four new epoxy adhesives in its LOCTITE’s bonding range – LOCTITE HY 4090, LOCTITE HY 4080, LOCTITE HY 4070, and LOCTITE HY 4060 GY, using the patented hybrid technologies. These adhesives are expected to meet the rising demands in assembly design and maintenance repair applications.

- Sika introduced SikaPower-4508, a one-component heat curing epoxy adhesive based on flexibilized epoxy resin to the US market in March 2018.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=142980020

Composite Film Market - Led by strong end-user demand

Composite films are used in a variety of end-use industries, including aerospace & defense, and automotive, among others. Led by strong end-user demand, the composite film industry is growing at a rapid pace. The global composite film market size is expected to grow from ~USD 245 million in 2020 to ~USD 328 million by 2025, at a Compound Annual Growth Rate (CAGR) of 6.0% during the forecast period.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=232995579

The aerospace & defense industry is a major consumer of composites, which in turn increases the demand for composite films. Leading aircraft manufacturers such as Boeing and Airbus are increasing the use of carbon composites, and composite films in their commercial aircraft. Composite films are also used in fuselage, wings, tail, tail fin, wing box, trailing edge, engine nacelles, engine, and other structural parts of an aircraft. Growing environmental concerns and search for high strength lightweight materials to increase fuel efficiency has put composites and simultaneously composite films under the limelight in the automotive industry. As, the composite structures used on automotive would require Class A protection from extreme climates, and scratches.

The strength-to-weight ratio of most composites is higher than that of steel and aluminum. The weight reduction of the required structure makes the use of composites vital in the aerospace & defense industry. The use of composite films in aircraft has grown as they are lightweight and have high tensile strength. Composite films can withstand lightning strikes. Commercial aircraft such as Boeing 787 and Airbus 350 are relying heavily on carbon fiber composites for their airframe structures, with 50% of the aircraft’s materials being composites, which in turn increases the demand for composite films.

North America holds the largest market for the composite film market. The key reason for this includes the demand for composite films in the aerospace & defense industry in the region. The demand for composite film in aerospace & defense, automotive, and other industries is projected to improve due to product innovation and technological advances made in this sector. According to the 24/7 Wall St. a Delaware corporation, in the US, parts of Florida experience an average of 100 thunderstorm days annually, making Florida the most likely place in the country for lightning strikes. Also, along the US West Coast, annually, an average of 10 thunderstorms is experienced. These factors drive the demand for composite films during the forecast period.

Key players in the market include 3M(US), Henkel AG Co. KGaA(Germany), Hexcel Corporation(US), Gurit (Switzerland), Solvay(Belgium), Toray Industries, Inc. (Japan), Socomore(France), Park Aerospace Corp.(US), and Axiom Materials Inc.(US), among many others. These companies are involved in adopting various inorganic and organic strategies to increase their foothold in the composite film market.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=232995579

Non-Biodegradable Plastics to Lead Bioplastics & Biopolymers Market During Forecast Period

In recent years, there has been a growing awareness that the use of non-biodegradable plastics is leading to large amounts of plastic waste ...

-

The global polylactic acid market is projected to reach $43.7 billion by 2024, growing at a CAGR of 5.2% from 2018. The industry is charact...

-

The global propylene glycol market was valued at USD 3.47 Billion in 2016, and is projected to grow at a CAGR of 5.8%, to reach USD 4.60 ...

-

In recent years, there has been a growing awareness that the use of non-biodegradable plastics is leading to large amounts of plastic waste ...