Sunday, 29 November 2020

Consumer interest in sustainably produced ingredients in cosmetic and personal care products driving the Cosmetic Pigments Market

The market size of cosmetic pigments is estimated at USD 698 million in 2019 and projected to reach USD 1,019 million by 2024, growing at a CAGR of 7.9%. The global cosmetic pigments market is driven by the growing demand from color cosmetic and personal care applications. Increased need for product differentiation and growing awareness about the improved appearance of products are boosting the market.

Several harmful chemicals are still being used as ingredients in makeup products. These chemicals may have an adverse effect on human health and can increase the risks of health hazard when several makeup products are used together. A combination of increased public interest and market trends in the cosmetics industry has led the cosmetics manufacturers to seek more natural and sustainable cosmetic emulsifiers. The demand for organic pigments, which are environment-friendly and are manufactured using sustainable technologies, is increasing rapidly. Manufacturing companies are investing to venture into the green market and are following sustainable technologies. The growing demand for cosmetic pigments that are manufactured using natural ingredients and organically produced from renewable raw materials is proving an opportunity for the cosmetic pigments market players.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=179525453

Facial Makeup is the fastest-growing application of cosmetic pigments.

Cosmetics products were traditionally made of chemical compounds; however, recently, there has been a significant demand for cosmetic products derived from natural sources. The application of cosmetic pigments includes nail products, lip products, eye makeup, facial makeup, hair color products, special effect & special purpose, and others (toothpaste, hair shampoo & conditioner, and sunless tabbing products). Facial makeup accounts for the largest application of cosmetic pigments market. The increasing demand for root makeup products such as foundations and face powders is expected to drive the market in this application segment.

APAC is the fastest-growing market, in terms of both production and demand. Higher domestic demand, easy availability of raw materials, and low-cost labor make APAC the most preferred destination for the manufacturers of cosmetic pigments. The use of cosmetic pigments as an important additive in various applications such nail products, lip products, eye makeup, facial makeup, hair color products, special effect & special purpose as is driving the market in China. APAC is emerging as a leading consumer of cosmetic pigments due to the increasing demand from domestic as well as international markets.

The key players in the cosmetic pigments market include Sun Chemical (US), Sensient Cosmetic Technologies (France), Merck (Germany), BASF (Germany), ECKART (UK), Sudarshan (India), Kobo Products (US), Clariant (Switzerland), and Geotech (Netherlands). These players have established a strong foothold in the market by adopting strategies such as expansion, new product launch, and merger & acquisition.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=179525453

Thursday, 26 November 2020

The growing number of commercial construction projects are expected to drive the modular chillers market

The modular chillers market size is estimated to be USD 2.6 billion in 2019 and projected to reach USD 3.5 billion by 2024, at a CAGR of 6.0%, between 2019 and 2024. Modular chillers is mainly used in the commercial, industrial, and residential applications for air conditioning, space cooling, and process cooling. They are energy efficient, compact, and easy to maintain as compared to their substitutes. The growing number of commercial construction projects are also expected to drive the modular chillers market.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=75609903The water-cooled segment accounted for the larger share in the modular chillers market

The water-cooled modular chillers segment dominated the modular chillers market, with a share of more than 70.0% in 2018. The water-cooled modular chillers use water and heat transfer fluids for cooling, making them very efficient compared to the air-cooled modular chillers, which utilize only ambient air for cooling. This has increased its demand in space and process cooling in the commercial and industrial applications.

Commercial to be the fastest-growing application segment of the modular chillers market

The demand for modular chillers has been gaining momentum in the HVAC industry as it is lighter, efficient, and lowers the required refrigerant volume as compared to other heat exchangers. Modular chillers are widely used in AC systems and heat pumps for efficient heat transfer between refrigerant and air. In the recent years, owing to the growing demand for lightweight systems and rising copper prices, the demand for modular chillers has increased in various HVAC applications. Moreover, because of compact design, lightweight, and lower hold-up volume, modular chillers are used in the residential and commercial cooling applications.

APAC is projected to be the fastest-growing modular chillers market

APAC is projected to be the fastest-growing market for modular chillers, owing to the presence of highly-populated countries, such as China and India. China, India, Japan, Indonesia, and South Korea are some of the key countries in the modular chillers market in this region. In 2018, China accounted for the largest share of the APAC market, owing to the presence of huge HVAC industries. The growing sales of HVAC systems and their increasing demand from commercial and residential infrastructure in the region boosts the demand for modular chillers. In addition, growing urbanization and population are mainly driving the demand for modular chillers in the HVAC systems.

Carrier Corporation (US), McQuay Air-Conditioning (Hong Kong), Johnson Controls- Hitachi Air Conditioning (Japan), Midea Group (China), Ingersoll Rand (Ireland), Gree Electric Appliances (China), Frigel Firenze (Italy), Mitsubishi Electric Corporation (Japan), Multistack (US), and Haier Group (China) are a few active players in the modular chillers market.

Request For Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=75609903

Wednesday, 25 November 2020

The eco-friendly production process of bio-based propylene glycol has led to the growth of the propylene glycol market

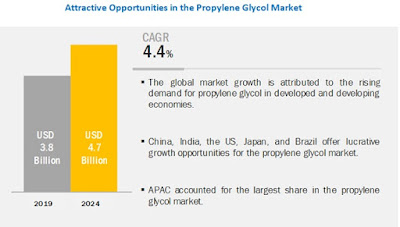

The propylene glycol market size is projected to reach USD 4.7 billion by 2024 from USD 3.8 billion in 2019, at a CAGR of 4.4%. The growing demand for propylene glycol in countries such as China, India, Japan, and South Korea from the transportation, building & construction, food & beverage, pharmaceuticals, and cosmetics & personal care industries is expected to fuel the growth of the market. The market is evolving, with major players playing a crucial role in the development of new and advanced products.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=264488864

On basis of source, the global propylene glycol market is segmented into petroleum-based and bio-based propylene glycol. Petroleum-based propylene glycol is expected to lead the global market during the forecast period, due to its growing use in the transportation and building & construction industries.

Unsaturated polyester resin to be the largest application segment

Unsaturated polyester resin is expected to dominate the global propylene glycol market during the forecast period, followed by antifreeze & functional fluids and pharmaceuticals. The growing building & construction industry, coupled with increasing investments in emerging economies for infrastructural development, is fostering the growth of the propylene glycol market in the unsaturated polyester resin application.

“Transportation to be the largest end-use industry"

On the basis of end-use industry, the global propylene glycol market is segmented into transportation, building & construction, food & beverage, pharmaceuticals, cosmetics & personal care, and others. Transportation is the fastest-growing end-use industry due to the growing automobile sales. The increase in the use of propylene glycols in applications, such as aircraft deicing fluid, automotive coolants, and hydraulic & brake fluids, is also driving the propylene glycol market.

APAC to account for the largest share of the global propylene glycol market

APAC is expected to account for the largest market share in the global propylene glycol market during the forecast period, in terms of both volume and value. The increasing population in the region, accompanied by increasing construction spending in the developing markets of China, India, and South Korea, is projected to make this region an ideal destination for the propylene glycol industry.

Request for Sample Request: https://www.marketsandmarkets.com/requestsampleNew.asp?id=264488864

Friday, 20 November 2020

Conformal Coating Market worth $1,265 million by 2025, at CAGR of 5.3%

The Conformal coatings market is estimated to be USD 977 million in 2020 and is expected to reach USD 1,265 million by 2025 at CAGR of 5.3%. Conformal coatings are a type of protective coatings of 25-75µm thickness which are applied to printed circuit boards (PCBs) and other electronic components to protect them from harsh environments such as dust, solvents, moisture, humidity, and high temperature. Conformal coatings increase the operational performance of PCBs assemblies by maintaining long-term surface insulation.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=216347388

“Automotive is the largest end-use segment in the overall conformal coatings market.”

The automotive industry has grown at a fast pace in the last decade, which led to the rapid evolution and increased consumption of electronics used in the vehicles. Currently, an average mid-range vehicle is loaded with technological features such as lane sensors, adaptive cruise control, in-car entertainment, and navigation. Also, the emergence of electric vehicle (EV), connected cars, and autonomous vehicles have resulted in a rapid surge in the advancement of electronics installed in these vehicles. From the industry point of view, the challenge is to protect these huge volumes PCBs and ICs used in the electronics system over a long period while meeting the specifications required by the automotive industry. This creates an attractive opportunity for conformal coatings manufacturers in the automotive and transportation industry. It is also the go-to-market for PCB manufacturers.

“Silicone conformal coating is the fastest-growing type for conformal coating.”

Various industries require coatings for high-temperature applications. Silicone conformal coatings are widely used for such applications, as they have the ability to withstand severe temperature conditions for an extended period. These coatings are widely used in under-the-hood automotive components. They can also be used in PCBs to protect them from damage and provide electrical insulation in hot and cold environments. Silicone coatings also protect electronic equipment from the extremely high as well as low temperatures. Silicone-based conformal coatings are manufactured as single-component compounds and also provides excellent humidity, corrosion and chemical resistance. However, these coatings are not abrasion resistant because of its rubbery nature, but this makes it resilient against vibrational stresses.

APAC is the largest market of conformal coatings, and this dominance is expected to continue till 2025. China is the key market in the region, consuming more than half of the demand for conformal coatings, followed by Taiwan, South Korea, and Japan. These countries are expected to witness a steady increase in consumption from 2020 to 2025. The region contributes close to 90% of PCB production in the world, and market is mainly driven by the presence of a large number of leading global electronics companies. PCB industry is quite fragmented as there are more than 100 companies that constitute close to 90% of overall PCB revenues and most of them belong to APAC, more so in China & Taiwan. Recent years have seen a lot of PCB manufacturing shifts to APAC due to cost-effectiveness and closer access to customers in the region, hence the increase in consumption of conformal coatings.

The key companies in the conformal coatings are Henkel (Germany), Illinois Tool Work (US), Shin-Etsu Chemical (Japan), Dow (US), H.B. Fuller (US), Chase Corporation (US), Electrolube (UK), Dymax Corporation (US), MG Chemical (Canada) and Specialty Coating System (US).

Request For Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=216347388

Thursday, 19 November 2020

The construction industry has the largest market share in the global phenolic panel

Phenolic panels are used in the interior, exterior, furniture, and various other applications of end-use industries, such as construction, marine, aerospace & defense, and transportation, to name a few. The main purpose of these phenolic panels is to offer fire-resistance and moisture-resistance properties. For instance, phenolic panels are used in the exterior cladding, partitions, cubicles, and other applications to prevent fire accidents. The global phenolic panel market size was USD 1.7 billion in 2020 and is projected to reach 2.4 billion by 2025, registering a growth of 6.5%.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=22703551

Phenolic panels used in the hot bond process comprises the major share of the market

The hot bond segment dominated the market in terms of value in 2019. Adhesives used in the hot bond process offers a strong, long-lasting repair with minimal risk of tearing, snagging, and other wear to the belt. They are mostly polyurethane-based and have a high demand for rubber conveyor belt repairing in the mining & quarrying industry.

Interior is the largest application of phenolic panel

Amongst all applications, the interior is the largest application of phenolic panel. Phenolic panels are used extensively for aircraft interior, railway interior, decorative interior in construction, partitions, and cubicles in various end-use industries. Superior fire-resistance and chemical resistance offered by the phenolic panel is responsible for the high consumption in an interior application.

Europe is the largest phenolic panel market globally.

The phenolic panel market is segmented based on region into Europe, North America, APAC, MEA, and South America. Europe is the major consumer of phenolic panels owing to the high demand from the UK, Germany, and other European countries. The UK is the leading market in the region. Major applications of phenolic panels in the European market include building interior, aircraft interior, exterior cladding, furniture, and air conditioning duct panels, among others. The growth of the market is also attributed to the presence of established manufacturers and technological advancement related to the development of phenolic panel products.

The key players in the market include Kingspan Group (Ireland), Wilsonart LLC(US), Asahi Kasei Corporation (Japan), Fiberesin Industries Inc. (US), Broadview Holding B.V. (Netherlands), Fundermax GmbH (Austria), Bobrick Washroom Equipment, Inc. (US), Werzalit of America, Inc. (US), ASI Group (US), and General Partitions Mfg. Corp. (US).These companies are adopting various inorganic and organic strategies to increase their foothold in the phenolic panel market.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=22703551

Thursday, 12 November 2020

Polymer Modified Cementitious Coatings Market worth $1.5 billion by 2025, at a CAGR of 6.5%

The polymer modified cementitious coatings market in 2020 is estimated at USD 1.1 billion and is projected to reach USD 1.5 billion by 2025, at a CAGR of 6.5% from 2020 to 2025. The growth of this market can be attributed to the increasing demand for polymer modified cementitious coatings from the residential buildings sector. In addition, government initiatives to support infrastructural developments in the Asia Pacific region are anticipated to drive the growth of the polymer modified cementitious coatings market. Furthermore, outbreak of COVID-19 pandemic is anticipated to hamper the consumption of polymer modified cementitious coatings which affects the market growth.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251464560

Flexible segment is projected to grow at the highest CAGR of the polymer modified cementitious coatings market

The flexible segment is estimated to lead the polymer modified cementitious coatings market in 2020. The growth can be attributed to superior waterproofing performance, excellent durability compared to non-flexible coatings, Flexible cementitious coating material has denser structure, better waterproofing performance, and excellent durability compared to non-flexible or rigid cementitious coatings. Flexible cementitious coatings are applied to objects which are subject to shrinkage, vibration, movement, stress, and crack formation and to substrates which are difficult to stick to, such as wood, steel, aerated lightweight blocks, and gypsum.

Acrylic polymers segment accounts for the largest share of the polymer modified cementitious coatings market

The acrylic polymers segment is estimated to lead the polymer modified cementitious coatings market in 2020, due to the rising demand due to increasing use of acrylic-based polymer modified cementitious coatings in residential buildings applications. Further, acrylic-based polymer modified cementitious coatings are low in alkali content, fast-setting, and high strength properties. These are also used for patching small cracks, holes, honeycombs, and surface defects over half-inch in depth. They are used in waterproofing floors, columns, beams, slabs, loading docks, and precast walls. They are also used for the protection of concrete structures from vapor, chloride ions, acidic gas, and alkali attacks.

Asia Pacific is expected to witness the fastest growth in the polymer modified cementitious coatings market during the forecast period

The polymer modified cementitious coatings market in the Asia Pacific region is projected to grow at the highest CAGR between 2020 and 2025. China, India, and Japan together accounted for the major share of the Asia Pacific polymer modified cementitious coatings market in 2019. The Asia Pacific region is an emerging and lucrative market for polymer modified cementitious coatings, owing to industrial development and improving economic conditions. This region constitutes approximately 60% of the world’s population, and thus leads to the wide-scale use of polymer modified cementitious coatings for waterproofing applications in residential and non-residential buildings, and public infrastructure. Outbreak of COVID-19 from China and the impact of coronavirus in Japan, South Korea, Autralia, and India has caused a decrease in the consumption of polymer modified cementitoi.

Major companies such as Arkema S.A. (France), Sika AG (Switzerland), Akzo Nobel N.V. (Netherlands), MAPEI S.p.A. (Italy), Compagnie de Saint-Gobain S.A. (France), and Fosroc International Limited (UAE) , Dow, Inc. (US) and H.B. Fuller Company (US) The Lubrizol Corporation (US), Organik Kimya Sanayi Ve Ticaret A.S. (Turkey), Pidilite Industries Limited (India), GCP Applied Technologies Inc. (US), Berger Paints India Limited (India), W. R. Meadows, Inc. (US), Evercrete Corporation (US), Indulor Chemie GmbH (Germany), The Euclid Chemical Company (US) and others are key players in the polymer modified cementitious coatings market.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=251464560

Sunday, 8 November 2020

The growing need to reduce CO2 emissions from industrial and power plants drives the demand for Carbon Capture, Utilization, and Storage system

Thursday, 5 November 2020

Optimal energy saving performance of insulating glass windows driving the market

The insulating glass window market is projected to grow from USD 12.8 billion in 2020 to USD 16.2 billion by 2025, at a CAGR of 4.8% from 2020 to 2025. The major reasons for the growth of the insulating glass window market include the optimal energy saving performance of insulating glass windows, the growing construction industry in regions like the Middle East and Asia Pacific, and the rising demand for value added glass products. These factors are responsible for driving the demand for insulating glass window market.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=36258309

Global energy demand continues to grow despite the historical high prices and mounting concerns over energy security. In order to address the issue of energy supply and demand, improving the energy efficiency of homes, businesses, schools, government buildings, and industries is imperative and inevitable. According to the U.S. Department of Energy (DOE), heating, cooling, and lighting of buildings account for 25% of the country’s total energy costs. This is expected to enhance the use of insulating glass windows for building insulation applications.

Commercial constructions that use insulating glass windows include commercial buildings, offices, hotels, hospitals, educational institutes, stadiums, and airports. Insulation helps reduce the heating and cooling loads of commercial buildings, manages indoor climate temperature, and reduces noise pollution, thus resulting in a more environmentally sustainable building. Furthermore, the increasing demand for Green Buildings in the commercial construction segment has been observed globally. These factors are expected to enhance the insulating glass window market during the forecast period.

Asia Pacific is projected to be the fastest-growing market during the forecast period. Growing demand for insulating glass window due to the increasing investments in the commercial construction sector, as well as government initiatives that support the use of insulating glass windows in commercial buildings. Furthermore, the presence of leading insulating glass window manufacturers is expected to drive the insulating glass window market in the region.

Compagnie de Saint-Gobain SA (France), AGC Inc. (Japan), Guardian Glass (US), Nippon Sheet Glass Co. Ltd. (Japan), and Central Glass Co., Ltd. (Japan) are some of the leading players operating in the insulating glass window market.

Henkel AG & Co. KGaA (Germany), Sika AG (Switzerland), and H.B. Fuller (US) are the key players in the adhesives & sealants for insulating glass window market..

Don’t miss out on business opportunities in Insulating Glass Window Market. Speak to our analyst and gain crucial industry insights that will help your business grow.

Wednesday, 4 November 2020

The food & agriculture packaging end-use industry is expected to be the largest consumer of thermoforming plastic, globally

The thermoforming plastic market is projected to grow from USD 34.8 billion in 2019 to USD 45.9 billion by 2024, at a CAGR of 5.7%. The thermoforming plastic industry is growing due to the rising healthcare & pharmaceuticals and food & agriculture packaging industries and increasing manufacturing activities. The increasing popularity of retail shopping and rising consumer spending for processed & packed goods are fuelling the demand for thermoforming plastic. Factors such as changing demographics and lifestyles have shifted the market toward e-retailing channels and convenient packaging, which in turn will drive the demand for thermoforming plastic.

Browse 143 market data Tables and 50 Figures spread through 173 Pages and in-depth TOC on "Thermoforming Plastic Market by Plastic Type (PP, PS, PET, PE, PVC, Bio-plastics, ABS), Thermoforming Type (Vacuum Formed, Pressure Formed, Mechanical Formed), Parts Type (Thin Gauge, Thick Gauge), End-use Industry, and Region - Global Forecast to 2024"

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=97181143

Thermoforming plastic finds application in food & agriculture packaging, healthcare & pharmaceutical, construction, electrical & electronics, automotive packaging & structures, consumer goods & appliances, and others. Food & agriculture packaging industry dominated the thermoforming plastic market in terms of value in 2018. This growth is attributed mainly to the huge demand for packaged and branded products. Thermoforming plastic provides better protection during transportation and uses safe packaging materials; hence, they are preferred in the food & agriculture packaging industry.

The thermoforming plastic market is segmented based on plastic-type as polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), polyethylene (PE), polyvinyl chloride (PVC), bioplastics, acronytrile butadiene styrene (ABS), and others. The global thermoforming plastic market is dominated by the PP, in terms of value and volume. This is due to the extensive use of this plastic in packaging applications such as food, medical device, and automotive. The excellent strength-to-weight ratio, excellent energy management, resilient, good chemical resistance, and durability make it an ideal choice for packaging applications.

North America accounted for the largest share in the global thermoforming plastic market. Technological advancements in the packaging industry primarily drive the market in this region. The demand for thermoforming plastic will be driven by factors such as increasing electronic goods sales, high disposable income, increasing demand for packaged foods, and demographic changes. The region is characterized by continuous technological advancements in the thermoforming plastic industry with the presence of some key regional players such as Pactiv LLC, Sonoco Products Company, D&W Fine Pack LLC, Fabri-Kal Corporation and Dart Container Corporation.

The US is a key market in North America. The increasing demand for consumer durables will drive the market for in the U.S. as thermoforming plastic finds growing use in it. The demand for thermoforming plastic in the US is likely to witness robust growth during the forecast period, as a result of the rising trend of retail shopping.

The thermoforming plastic market comprises major solution providers, such as Fabri-Kal Corp. (US), Berry Global Inc. (US), Genpak LLC (US), Pactiv LLC (US), D&W Fine Pack LLC (US), Amcor Ltd. (Australia), Dart Container Corp. (US), Anchor Packaging (US), Sabert Corporation (US), Sonoco Products Company (US). The study includes an in-depth competitive analysis of these key players in the thermoforming plastic market, with their company profiles, recent developments, and key market strategies.

Get This Report: https://www.marketsandmarkets.com/Purchase/purchase_reportNew.asp?id=97181143

Monday, 2 November 2020

Impact Modifiers Market worth $5.0 billion by 2025, at a CAGR of 5.3%

The demand for high-quality plastics from various applications increases continuously, which favors the consumption of engineering plastics. Further, rising demand for applications, such as pipes & fittings, profiles & tubing, rigid sheet & panel, wires & cables, bottles, and others, is fueling the demand for PVC, which contributes to the impact modifiers market growth. Furthermore, the outbreak of the COVID-19 pandemic is anticipated to hamper the consumption of impact modifiers, which affects the market growth.

Download PDF Brochure to Know More: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=58674504

PVC is the major application in the global impact modifiers market

PVC is the largest application segment of the impact modifiers market by application. The growth of impact modifiers in PVC application is mainly attributed to its easy availability and low cost as well as the increasing applicability of PVC among varied end-use industries, such as packaging, construction, automotive, and consumer goods. PVC is mainly used in pipes, windows, flooring, roofing, inflatable structures, and lighter structures. It contributes to the quality, cost-effectiveness, and safety of construction material.

Packaging is projected to grow at the highest CAGR of the impact modifiers market

Based on the end-use industry, the packaging segment is expected to grow at the highest CAGR in 2019. Increasing demand for plastic packaging with impact modifiers across varied industry verticals is expected to be one of the key factors propelling the growth of the impact modifiers market. The packaging is a crucial process in order to preserve and transport goods. It caters to various sectors such as retail, institutional, and industrial.

The impact modifiers market in the Asia Pacific region is projected to grow at the highest CAGR between 2020 and 2025. China, India, and Japan together accounted for the major share of the Asia Pacific impact modifiers market in 2019. Moreover, the Asia Pacific region is an emerging and lucrative market for impact modifiers, owing to industrial development and improving economic conditions. The presence of a number of plastic products manufacturing plants in China and rapid industrialization in Asia Pacific are expected to drive the impact modifiers market during the forecast period.

Request for Sample Request: https://www.marketsandmarkets.com/requestsampleNew.asp?id=58674504

Growing demand for furfuryl alcohol drive the Furfural Market

The furfural market size is estimated to grow from USD 551 million in 2019 and to USD 700 million by 2024, at a CAGR of 4.9%. The increasing usage of various derivatives of furfural in different industries and shift toward green chemicals are propelling the market.

Download PDF Brochure to Know More: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=101056456

“The derivatives application is expected to register the fastest growth”

Furfural is used as the starting material for the manufacturing of several furan derivatives, such as furfuryl alcohol, tetrahydrofuran (THF), maleic anhydride (MA), 2-methyl tetrahydrofuran (MTHF), and 1, 5-pentanediol.

Furfuryl alcohol manufacturing dominates the global furfural market. Furfuryl alcohol is majorly used for the production of furan resin that is used as a foundry sand binder. According to the IKB Deutsche Industriebank, the foundry industry is expected to grow in the coming years, majorly driven by the emerging markets. The growth of the foundry industry is expected to increase the demand for foundry resins. This, in turn, is likely to drive the demand for furfuryl alcohol, globally. Also, with the increasing focus on biochemicals and biofuels, the demand for other furfural-based derivatives is increasing, thereby driving the demand for furfural.

“APAC was the largest furfural market in 2018.”

APAC led the overall furfural market in 2018. The main reason for the growth of the market in the region is China, which has 85% and 75% of global production and consumption of furfural, respectively. The demand is attributed to the growing foundry and pharmaceutical industries in China. In addition, Thailand has emerged as the second-largest producer and exporter of furfural in the region.

The leading players in the furfural market are Transfuran Chemicals (Belgium), Central Romana Corporation (Dominican Republic), Pennakem (US), Silvateam (Italy), Illovo Sugar (South Africa), Hongye Holding Group Corporation (China), KRBL(India), Lenzing (Austria), Tanin (Slovenia), and Shandong Crownchem Industries (China).

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Non-Biodegradable Plastics to Lead Bioplastics & Biopolymers Market During Forecast Period

In recent years, there has been a growing awareness that the use of non-biodegradable plastics is leading to large amounts of plastic waste ...

-

The global polylactic acid market is projected to reach $43.7 billion by 2024, growing at a CAGR of 5.2% from 2018. The industry is charact...

-

The global propylene glycol market was valued at USD 3.47 Billion in 2016, and is projected to grow at a CAGR of 5.8%, to reach USD 4.60 ...

-

In recent years, there has been a growing awareness that the use of non-biodegradable plastics is leading to large amounts of plastic waste ...